How is the temperature controlled for a three roll machine

2024-08-05 15:40:09The temperature control method of the three roll machine is mainly achieved through fluid media.

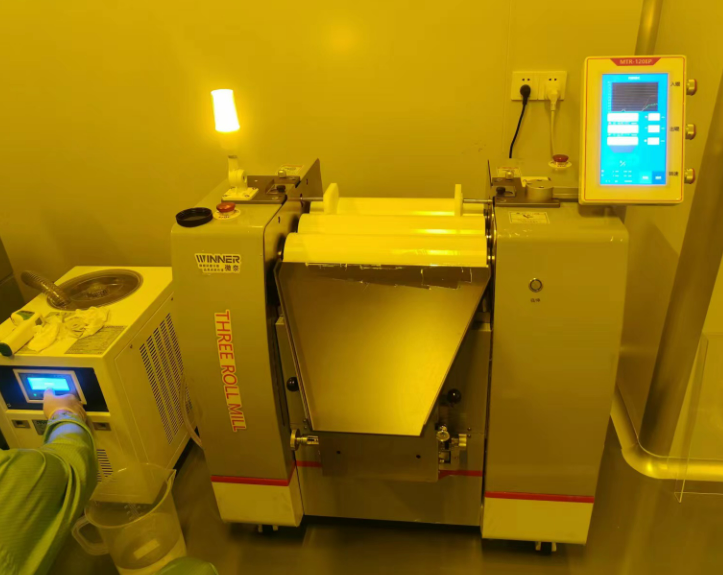

A three roll mill, also known as a three roll grinder, consists of three rollers. Its basic principle is to control the temperature through the fluid medium inside the roller, transmitting the temperature of the fluid to the surface of the roller to achieve the purpose of controlling its temperature. The design of this device enables precise temperature control, ensuring that the material reaches the desired temperature during processing, thereby improving production efficiency and product quality.

The three roll grinder itself comes with a water circulation interface, which, combined with an external independent temperature control unit, can flexibly control the temperature of the rollers.

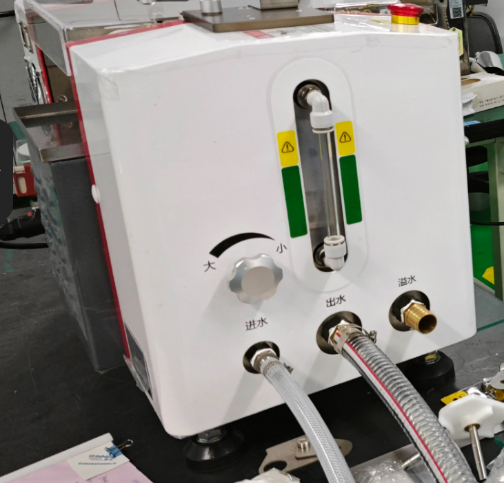

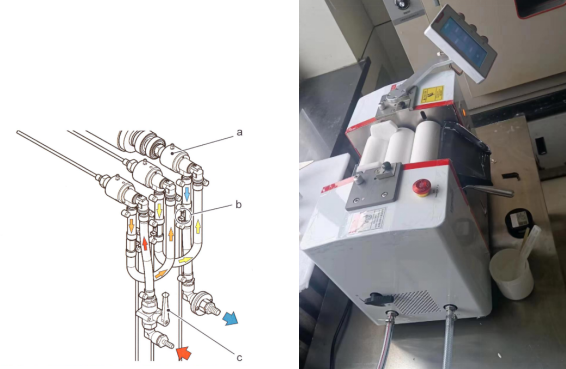

Open water tank structure (new version)

Sealed water tank structure (old version)

The built-in water circulation interface of the three roll machine is mainly divided into open structure and closed structure. The structure is as shown above. For the three roll machine of Weinai, the full range of temperature control structure equipment can directly display temperature on the human-machine interface. The two types of water tank structures on the market are shown in the above picture. The specific differences and advantages and disadvantages can be discussed by phone.

News

2024-02-29 15:58:05

2024-02-29 15:58:05

Innovative research and development concepts and technologies have enabled our new products to stand out in the same industry

2024-09-09 09:11:35

2024-09-09 09:11:35

CMPE 2024 WINNWE MTR-65EP Three roll Machine Shocking Attack

2024-07-10 08:47:14

2024-07-10 08:47:14

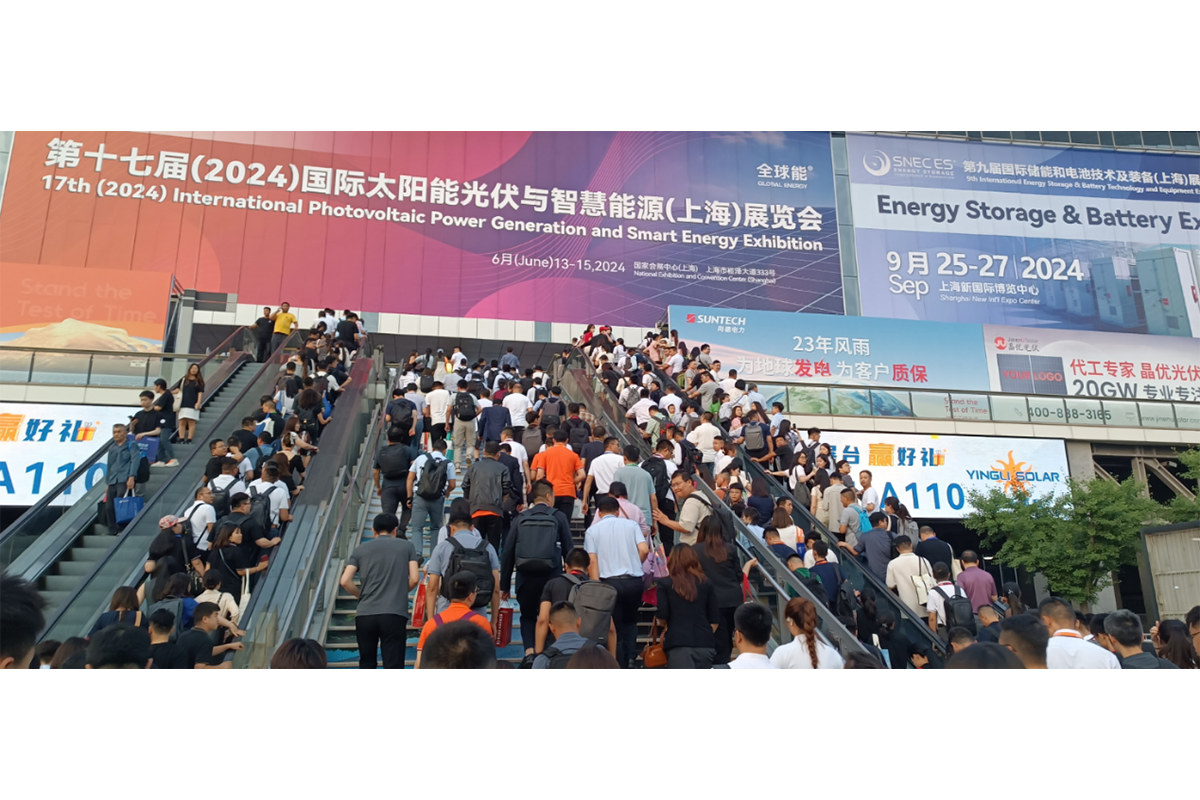

WINNER's full series of intelligent three roll machines debut in SNEC 2024

2024-07-10 08:59:06

2024-07-10 08:59:06

SAMPE China 2024, WINNER Intelligence Helps Aviation Composite Industry