How to distinguish between homogenizer and mixed defoamer

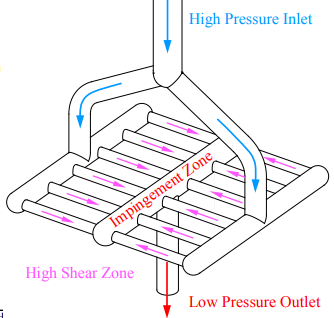

2024-08-05 15:37:30Homogenizer: It is an advanced high-pressure processing technology based on ultra-high pressure theory, fluid mechanics theory, and impact flow theory. It integrates various unit operations such as conveying, mixing, ultrafine grinding, pressurization, and expansion, and can perform a series of comprehensive effects on fluid mixed materials, including strong shearing, high-speed impact, instantaneous pressure release, high-frequency oscillation, expansion, and cavitation, thereby achieving excellent ultrafine, microemulsion, and homogenization effects. Dynamic ultra-high pressure technology represents an important innovation as it can be used to modify emulsions or biopolymers and can be applied in industrial production.

During the processing, the material is compressed for a very short time (less than 0.001s), but the pressure change rate is large, and the pressure can rise to 300MPa. At the same time, two or more micro jets of bullet type (with a speed of up to 500m/s) pass through the ultra-high shear of the diamond cavity in the homogeneous cavity, and then separate from each other in the diamond Y-shaped pore, and then collide with each other. During the process, through the effects of collision explosion, high-frequency shear oscillation, cavitation, pressure drop, etc., the material achieves nanoscale uniform refinement.

.png)

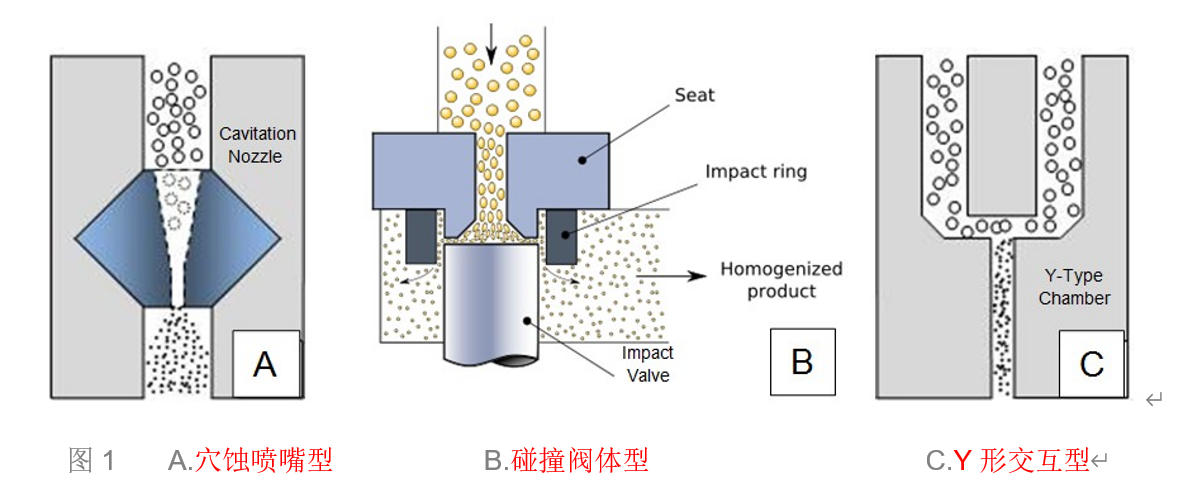

Homogeneous cavities can be divided into three types based on the internal structural details

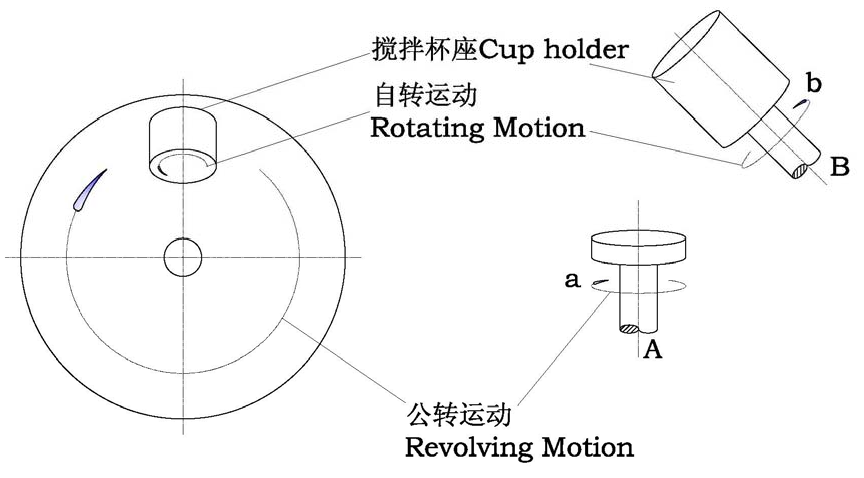

Mixing defoamer: Traditional mixing blade mixers suffer from various problems such as material occupying the container cup wall, loss on the mixing blades, material entanglement, and mixing dead corners, which can lead to uneven mixing. The hybrid defoamer utilizes the principle of natural gravity acceleration to impart kinetic energy to the movement of materials, causing them to generate forces between each other and then collide with each other. The kinetic energy is converted into the energy required for stirring, and the entire movement process is controlled in a vacuum negative pressure environment to remove submicron level bubbles that are invisible to the naked eye.

The revolution motion rotates around the arrow A in the figure. The revolution occurs in the direction indicated by the arrow "a" in the figure. When the system only has orbital motion, it has the same effect as applying centrifugal force separation. The rotational motion revolves around the arrow B in the figure. Rotation occurs in the direction of the arrow marked "b" in the graph. This system cannot work only during rotational motion, and the rotational speed of both orbital and rotational motion can be adjusted on this system.

When the slurry revolves around the cup, it is subjected to centrifugal force, and the specific gravity separation motion generated along the vector direction and the upward pushing effect generated by the self weight of the material separate the bubbles, playing a role in defoaming; At the same time, when the material rotates in the cup, the centrifugal vector synthesis force formed by the rotation of the cup produces a mixing and dispersing effect through the shear force between the material and the cup wall, as well as the friction between the internal molecules of the material, ultimately achieving the functions of defoaming and stirring.

The advantages of a mixed defoamer are as follows:

2.1. This process method has a high defoaming rate and can prepare a formula every 2-3 minutes;

2.2. It can be suitable for materials of different viscosities, has a wide range of applications, and greatly improves the upper limit of carrier solid content dissolution;

2.3. Stepless balance adjustment, centrifugal force can reach up to 400G

2.4. The revolution/rotation speed is continuously adjustable from 0-2000rpm, and multiple sets of formulas can be set. Each set of formulas can be controlled with multiple different parameters;

2.5. Multiple security protection mechanisms, high equipment process stability, and high safety;

2.6. Can meet the production needs of several grams to tens of liters in the laboratory;

2.7. High speed and temperature control, can be further matched with refrigeration units in terms of cooling and temperature control;

2.8. Gear transmission, precise meshing, high load, long service life, maintenance free

2.9. High vacuum, vacuum segmented control, removes sub micron level bubbles that are not visible to the naked eye.

3. Some of our competitors refer to the mixing defoamer as a homogenizer, which has a certain degree of guidance and may cause customers searching for mixing defoamers to find high-pressure homogenizers, inevitably leading to some questions. The main functions of homogenizers are emulsification, crushing, and dispersion; The main function of the mixing and defoaming machine is to mix and defoam. It has many advantages due to the lack of stirring medium, but only one fatal disadvantage is that its dispersing and crushing force is very small, which can mix evenly, but cannot open the small aggregates generated during the mixing process.

News

2024-02-29 15:58:05

2024-02-29 15:58:05

Innovative research and development concepts and technologies have enabled our new products to stand out in the same industry

2024-09-09 09:11:35

2024-09-09 09:11:35

CMPE 2024 WINNWE MTR-65EP Three roll Machine Shocking Attack

2024-07-10 08:47:14

2024-07-10 08:47:14

WINNER's full series of intelligent three roll machines debut in SNEC 2024

2024-07-10 08:59:06

2024-07-10 08:59:06

SAMPE China 2024, WINNER Intelligence Helps Aviation Composite Industry