Main functions and application scenarios of the revolving and rotating mixer

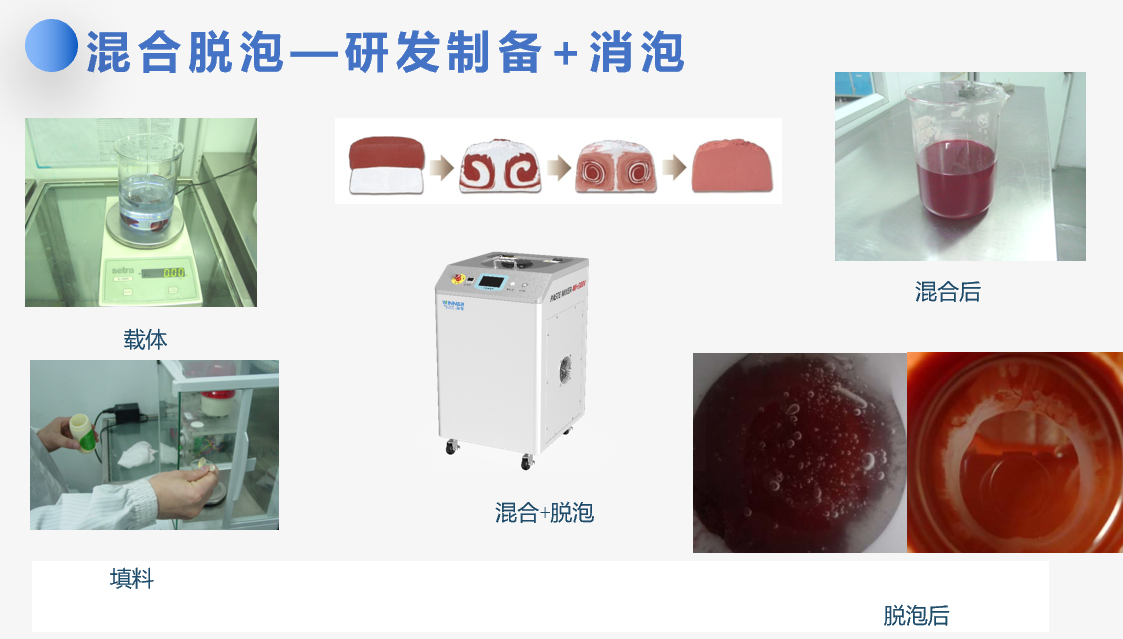

2024-08-05 15:32:38The main function of the mixing defoamer is to mix and defoam, as shown in the following schematic diagram

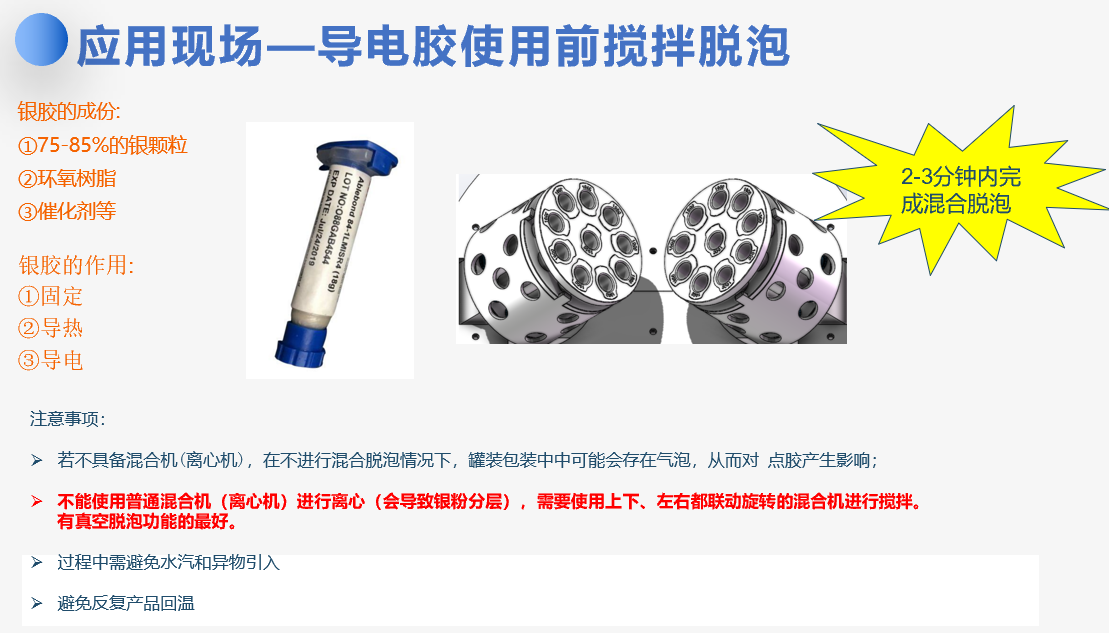

Can be applied for defoaming in different scenarios of containers, as follows in the conductive adhesive industry

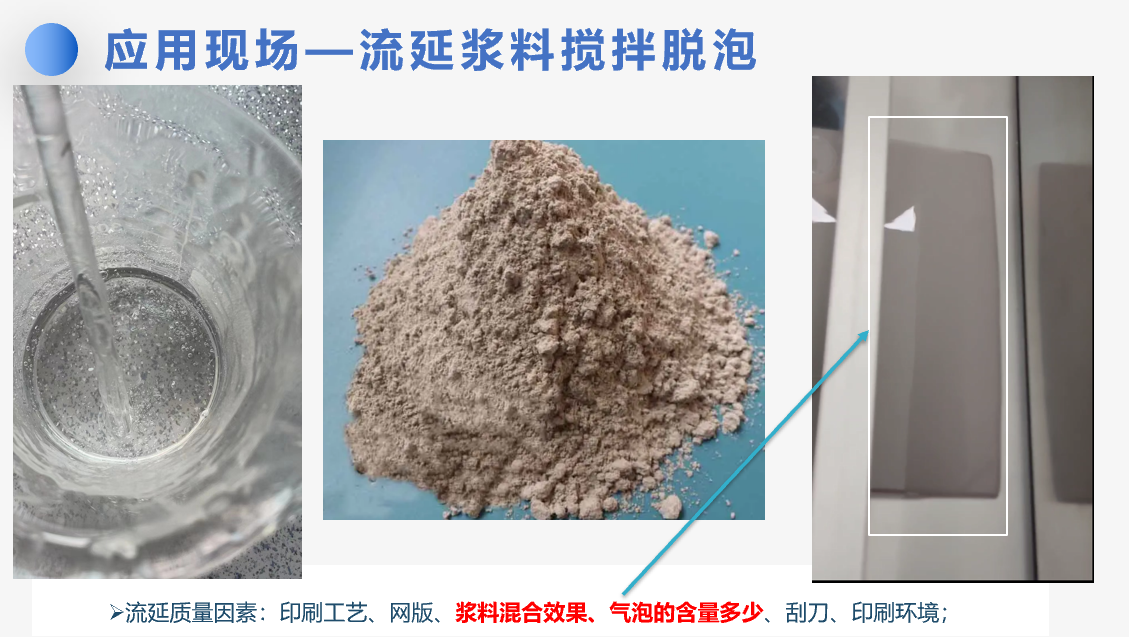

The mixed defoamer is suitable for the application of materials with different solid contents and viscosities. The following is the mixed defoamer for ceramic slurry

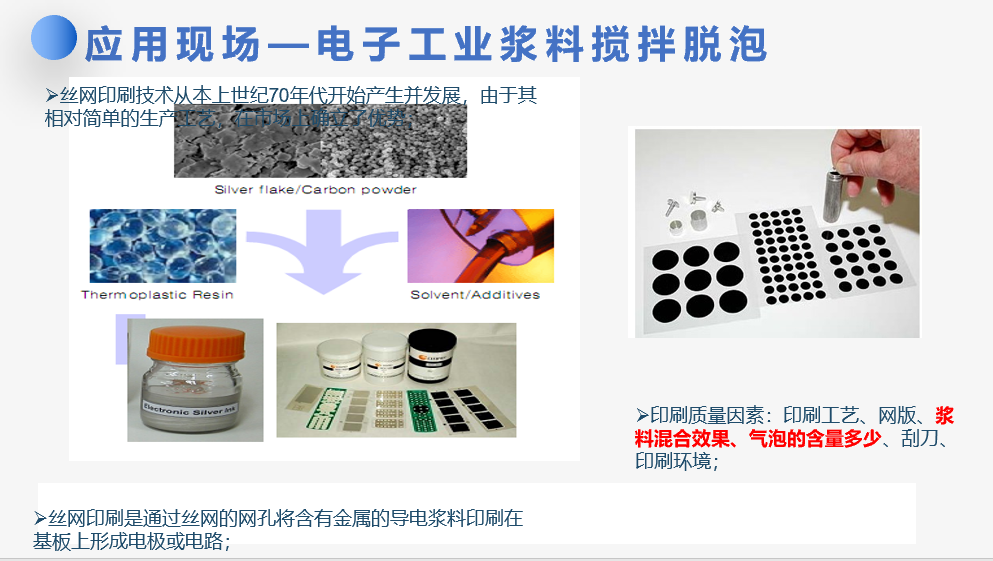

The mixed defoamer has many applications not only in the field of adhesive preparation, but also in the field of pulp. The following are some applications of our equipment in printing pulp

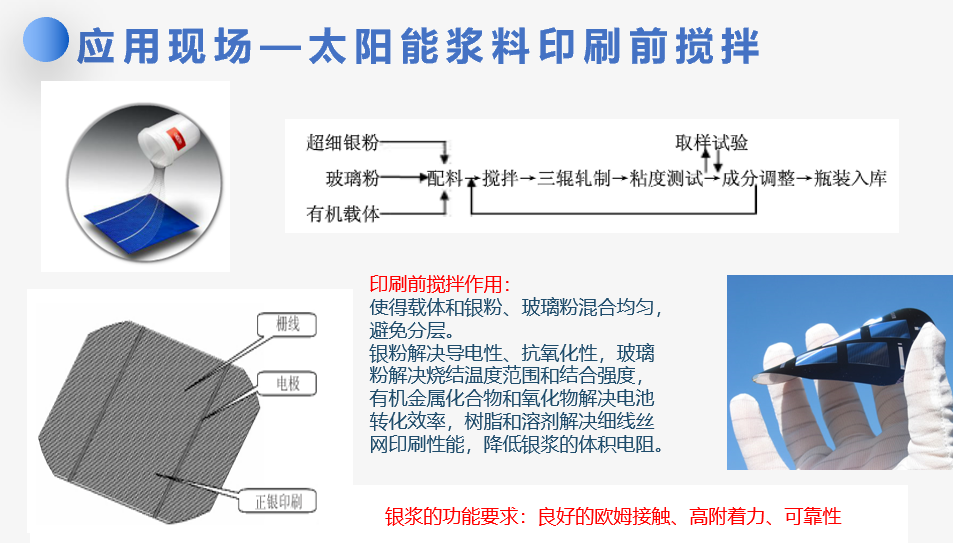

The mixed defoamer also plays an important role in the short photovoltaic slurry, as it ensures uniform mixing of the carrier with silver powder and glass powder, avoiding delamination.

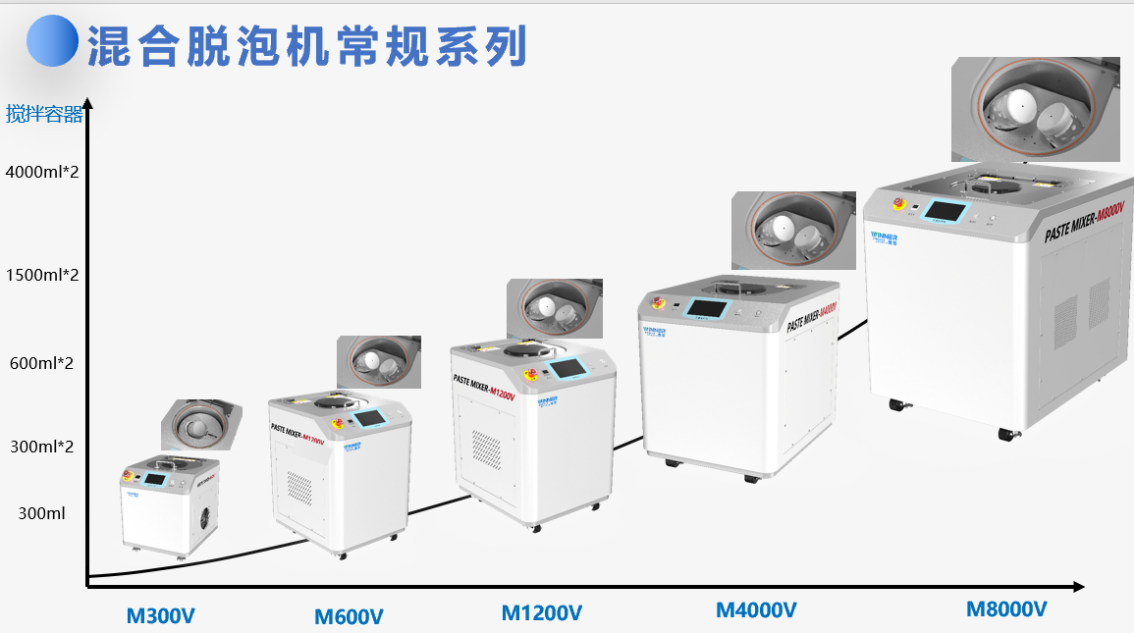

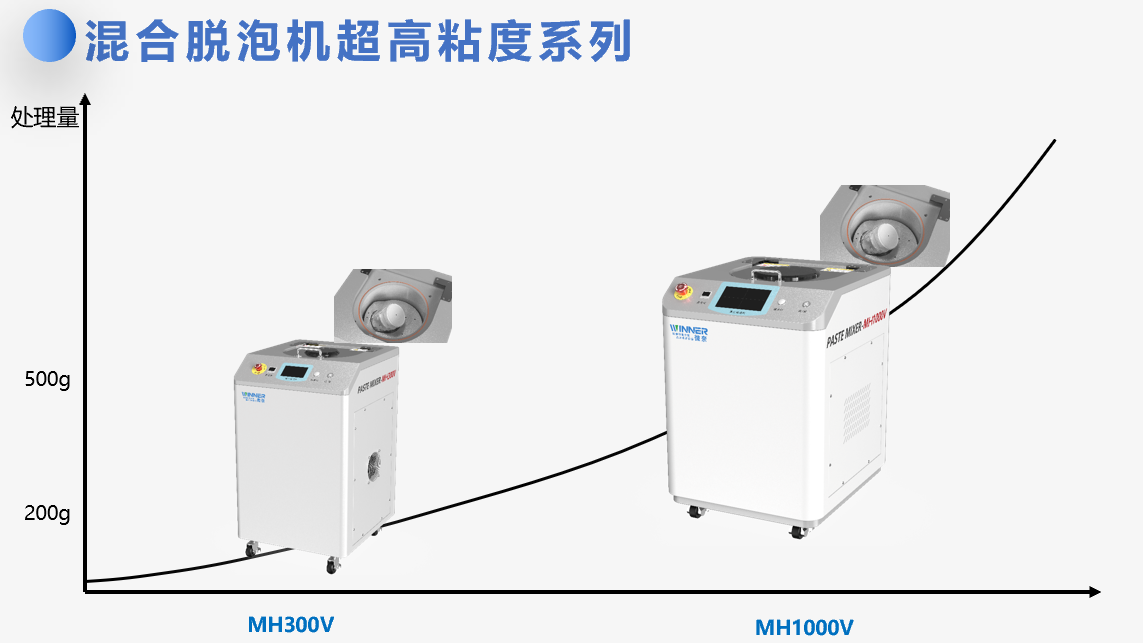

There are two main types of mixing defoamers for micro nano: high viscosity and low viscosity. The specific differences can be discussed in detail over the phone.

News

2024-02-29 15:58:05

2024-02-29 15:58:05

Innovative research and development concepts and technologies have enabled our new products to stand out in the same industry

2024-09-09 09:11:35

2024-09-09 09:11:35

CMPE 2024 WINNWE MTR-65EP Three roll Machine Shocking Attack

2024-07-10 08:47:14

2024-07-10 08:47:14

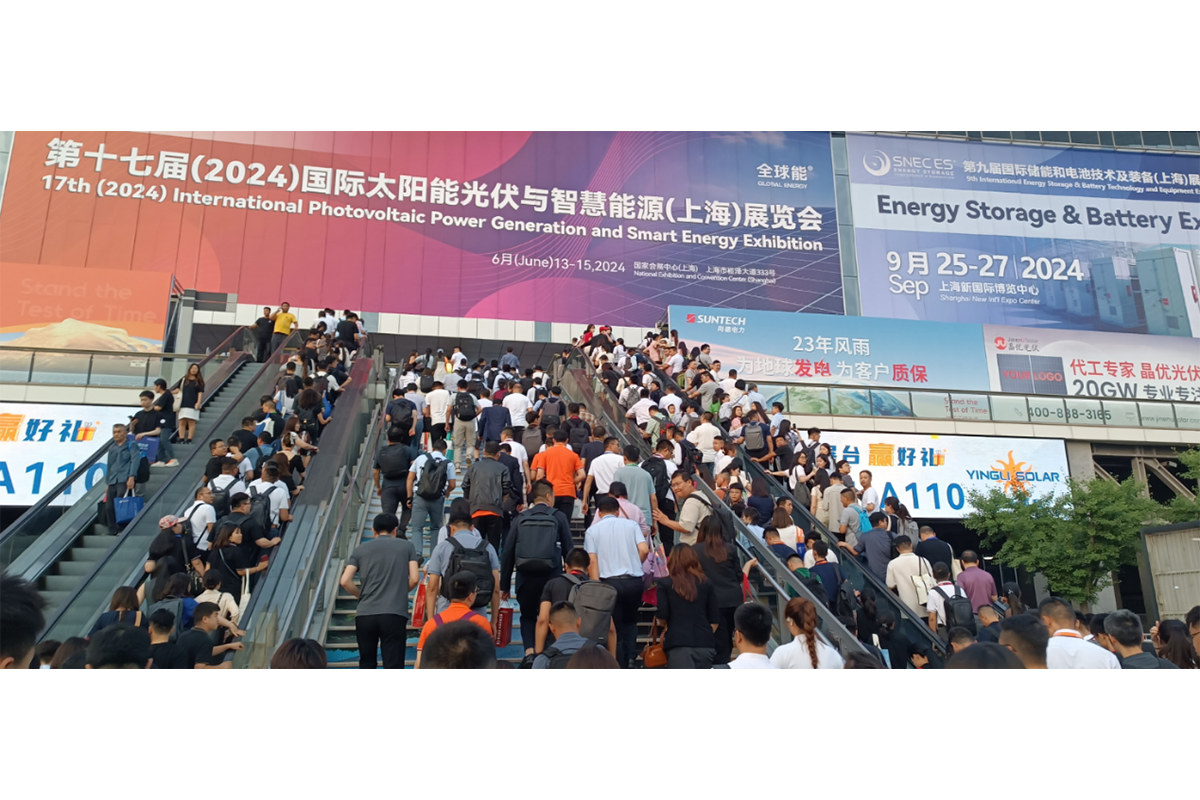

WINNER's full series of intelligent three roll machines debut in SNEC 2024

2024-07-10 08:59:06

2024-07-10 08:59:06

SAMPE China 2024, WINNER Intelligence Helps Aviation Composite Industry