What is a revolving self rotating mixer and what is its role in material research and development

2024-07-30 14:36:55Centrifugal mixing and defoaming machines play an important role in many industrial fields, such as electronics, chemical engineering, pharmaceuticals, etc. It can effectively remove bubbles from materials, saving a lot of time for R&D colleagues to quickly make formulas and improving product quality and performance.

The WeiNai's stirring defoaming machines plays a crucial role in various material processing and production processes. Next, we will provide a detailed introduction to the operation mode of the revolving and rotating mixer and its role in materials.

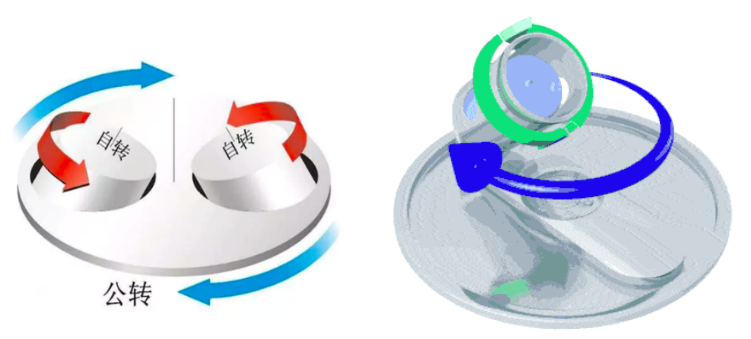

1、 Model display of rotary stirring and defoaming machine

2、 Display of the operating status of the rotary mixing machine

As shown in the above figure, the operating status of the equipment can be intuitively understood. The rotating cup of the equipment revolves around the center point, and the overall rotation is called revolution. The rotating cup rotates on its own, and the rotation speed can be set freely according to the material requirements. The maximum rotation speed of a single cup equipment is 3000 revolutions, with a fixed ratio. The rotation speed is in the opposite direction, with a ratio of 0.7, which can be easily understood as revolution of 1000 revolutions and rotation of 700 revolutions. The rotation ratio of a double cup equipment can be adjusted according to the material requirements. The rotation ratio range is 0-100. The equipment moves in different directions through the rotation speed ratio, causing the material to form vortices in the cup. The material self rubs and stirs, thereby generating centrifugal force, squeezing sub micron sized bubbles in the material onto the surface. Using the vacuum mode of the equipment, all surface bubbles are removed.

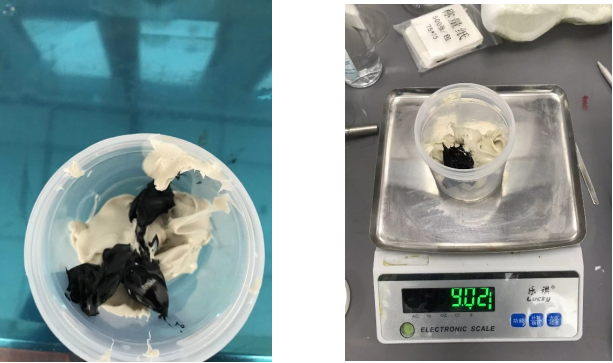

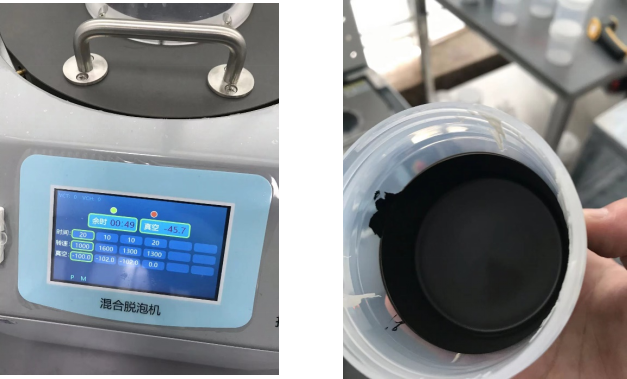

3、 Case Presentation

As shown in the above figure, the materials are proportioned according to their proportions

Through the stirring and defoaming machine of Weinai, the mixing and defoaming of materials can be completed within 1-2 minutes. Under the same parameter mode and material ratio, the repeatability is extremely high, greatly freeing up the hands of R&D personnel and improving the efficiency of R&D work. Multiple formulas can be verified in a short period of time.

News

2024-02-29 15:58:05

2024-02-29 15:58:05

Innovative research and development concepts and technologies have enabled our new products to stand out in the same industry

2024-09-09 09:11:35

2024-09-09 09:11:35

CMPE 2024 WINNWE MTR-65EP Three roll Machine Shocking Attack

2024-07-10 08:47:14

2024-07-10 08:47:14

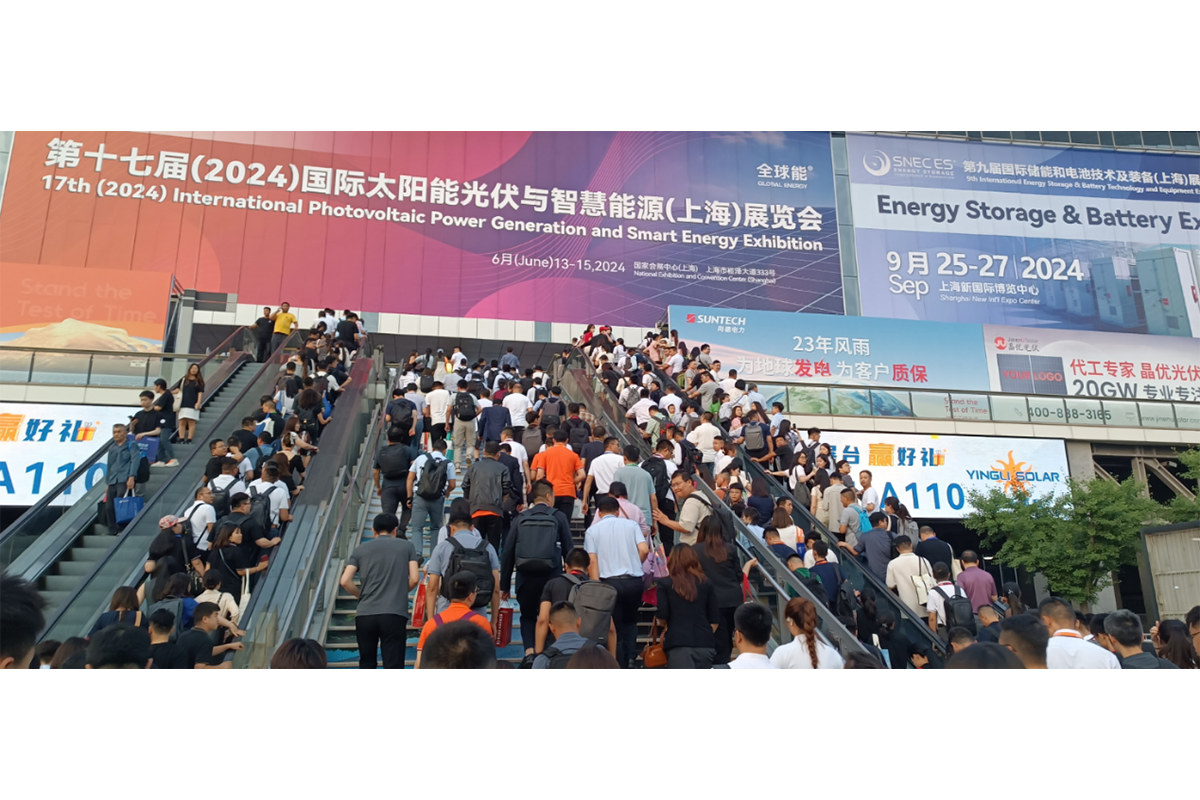

WINNER's full series of intelligent three roll machines debut in SNEC 2024

2024-07-10 08:59:06

2024-07-10 08:59:06

SAMPE China 2024, WINNER Intelligence Helps Aviation Composite Industry