Working principle of three roll grinder

2024-07-30 14:24:07In modern industrial production, high-precision material processing equipment is crucial for improving product quality and performance. As an advanced material processing equipment, Weinai's intelligent high-precision three roll machine has been widely used in many fields due to its excellent performance and intelligent characteristics.

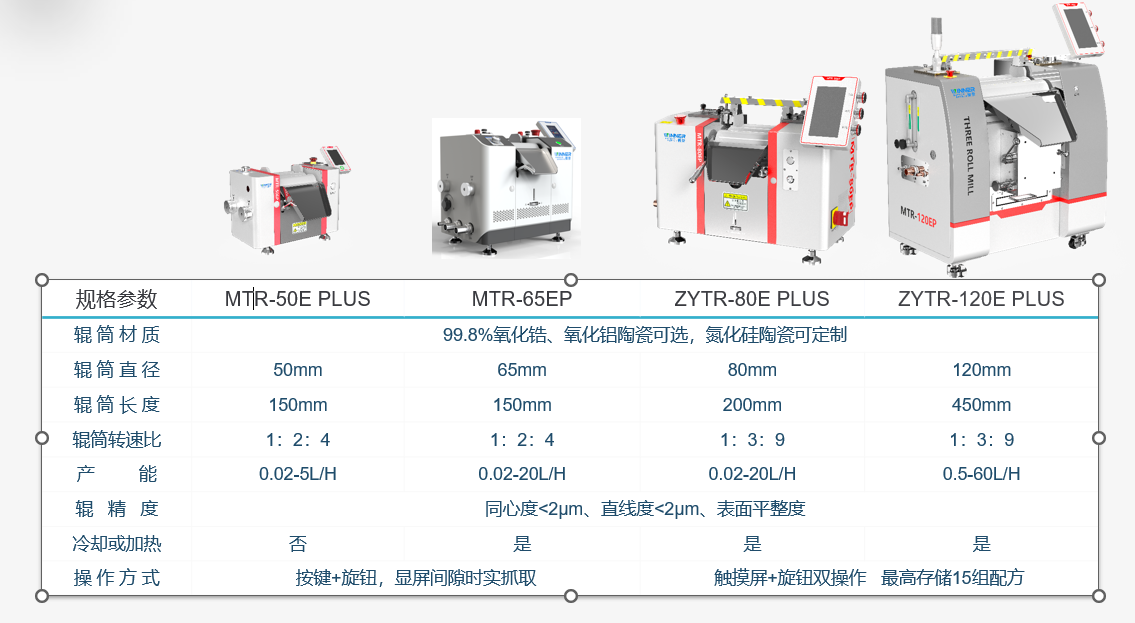

1、 Three roll grinder model display

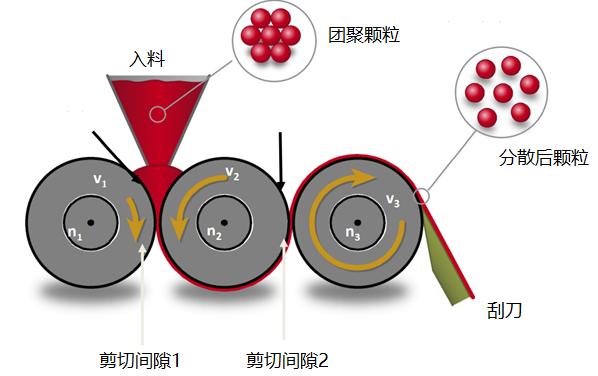

2、 Working principle of three roll grinder

The working principle of the WeiNai intelligent high-precision three roll machine is based on the relative rotational motion of the three rollers.

The material is subjected to compression, shear, and friction between the rollers, thereby achieving processes such as grinding and dispersion.

The three roll grinder generates a large shear force through three horizontal rollers, different gaps, and different rotational speeds, effectively grinding and dispersing agglomerated particles held together;

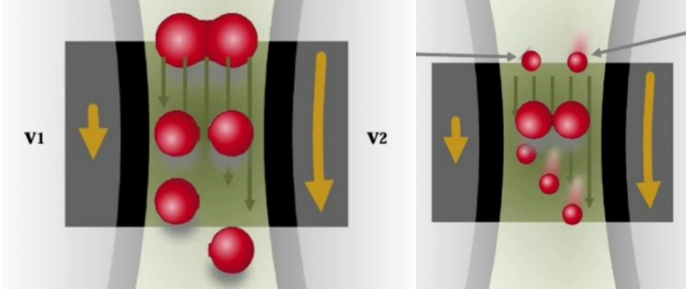

As shown in the figure, the state of the material between the rollers is displayed

During the work process, the speed and pressure of the three rollers can be precisely adjusted as needed. Usually, the speed of the discharge roller is the fastest, followed by the middle roller, and the feed roller is the slowest, forming a speed difference with a speed ratio of 4:2:1 and 9:3:1. Due to the difference in roller speed, the gap is generally adjusted to a two-fold relationship. The gap between the feed roller and the discharge roller should be larger than that of the feed roller, such as the 40/20 gap model, which generates strong shear force and allows the material to be fully processed.

News

2024-02-29 15:58:05

2024-02-29 15:58:05

Innovative research and development concepts and technologies have enabled our new products to stand out in the same industry

2024-09-09 09:11:35

2024-09-09 09:11:35

CMPE 2024 WINNWE MTR-65EP Three roll Machine Shocking Attack

2024-07-10 08:47:14

2024-07-10 08:47:14

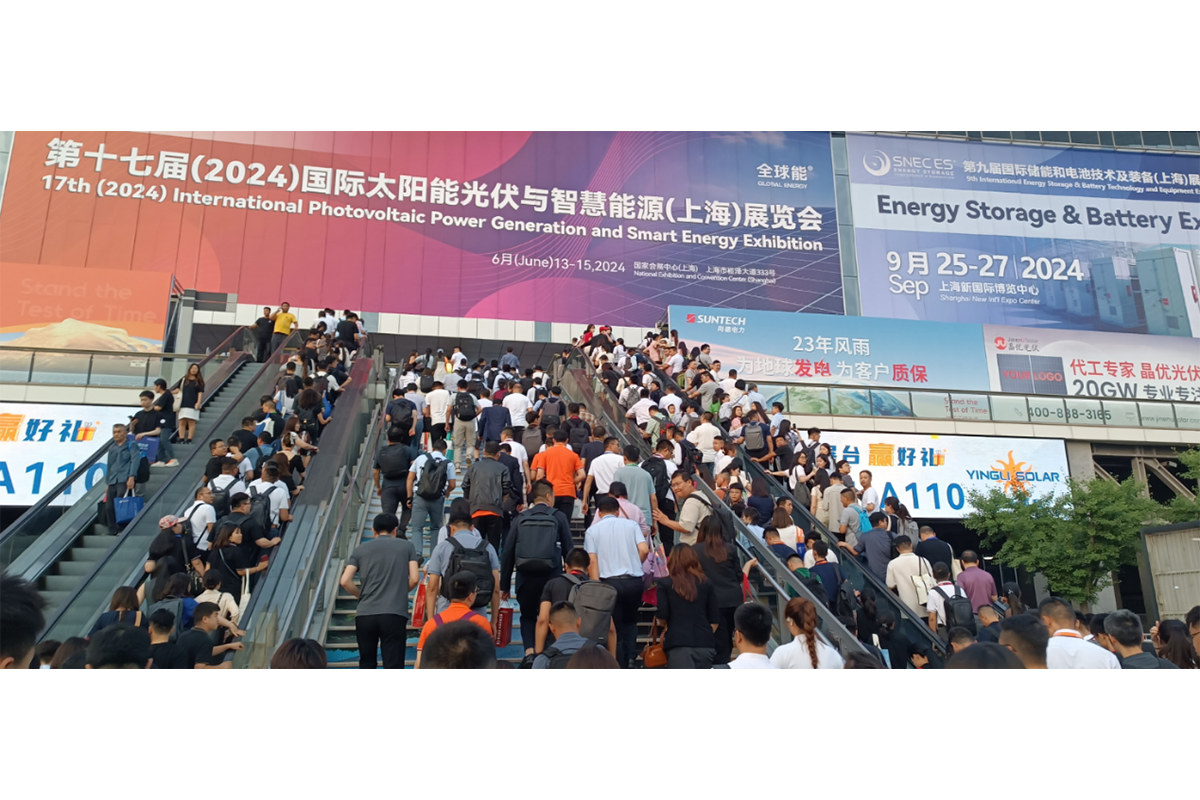

WINNER's full series of intelligent three roll machines debut in SNEC 2024

2024-07-10 08:59:06

2024-07-10 08:59:06

SAMPE China 2024, WINNER Intelligence Helps Aviation Composite Industry